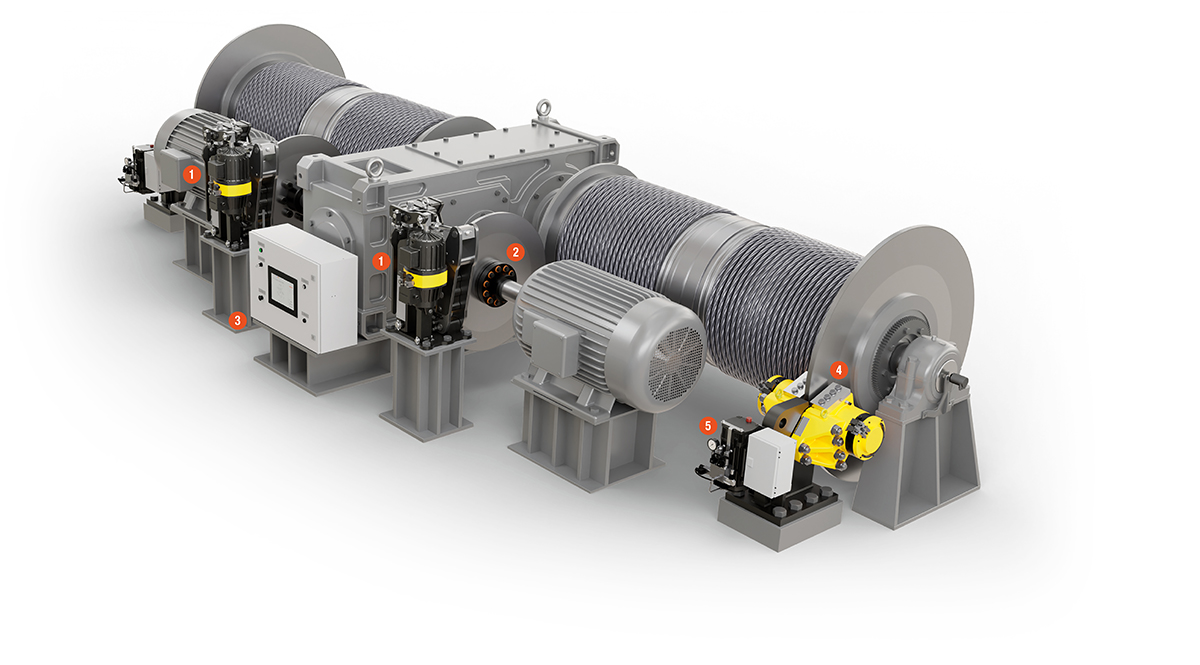

RINGSPANN in Main & Boom Hoists and Trolleys

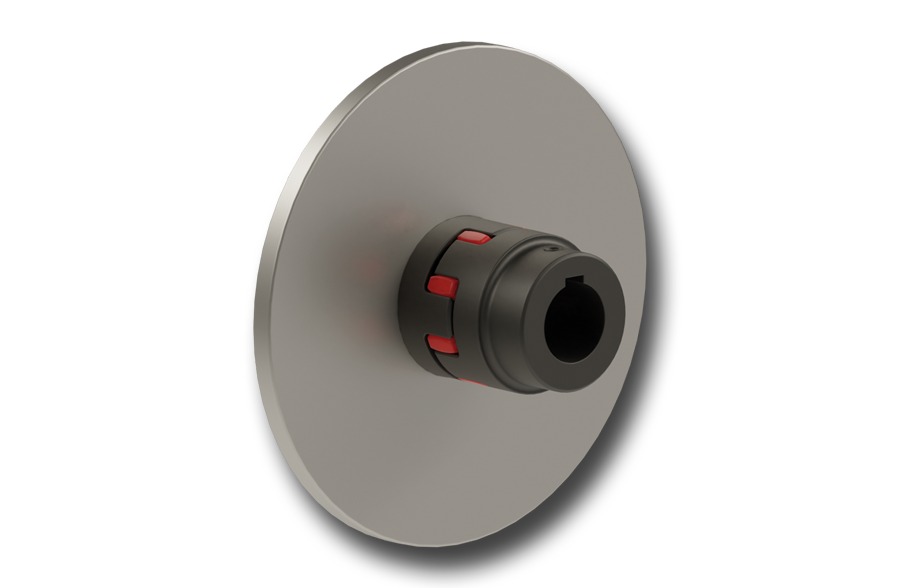

Electrohydraulic Thruster Brakes and Couplings for Hoists

Pin and Bush and Jaw Couplings with Brake Disc

- Brake disc diameter up to 1 000 mm

- Maximum transmittable torques of up to 337 kNm

- Fail-safe torque transmission

- Compensation of axial, radial and angular misalignments

- Low maintenance

- Complies with ATEX 2014/34/EU

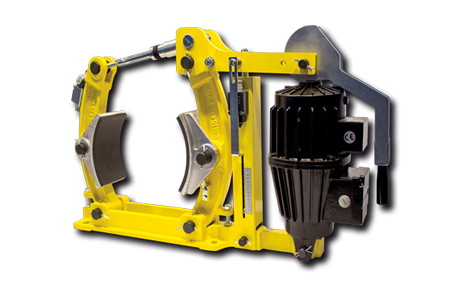

Electrohydraulic Thruster Brakes

- Robust self centering unit, that is easy to adjust

- Encapsulated automatic wear compensation unit

- Maintains parallel pad air gap when brake is released

- Very high braking force in a lightweight design

- Brake peak heights in accordance with the market standard: 160 mm, 230 mm, 280 mm and 370 mm

Electrohydraulic Thrusters for Hoists

Electrohydraulic Thrusters with gear pump

- For critical applications like main hoists and trolleys

- Pressure generation via gear pump

- Lifting forces up to 8 kN

- Ultra fast setting times (< 80 ms)

- 100% analogue layout – no circuit board required

- Proven 3-phase connection

- Very low power consumption due to unpressurised circulation, while brake is open

- Easy maintenance - wearing parts, such as solenoid coils, can be replaced while the thruster is installed in the brake

Electrohydraulic Thrusters with impeller pump

- Proven design with an impeller pump for pressure generation

- Simple and robust - easy to maintain design

- Lifting forces up to 4,5 kN

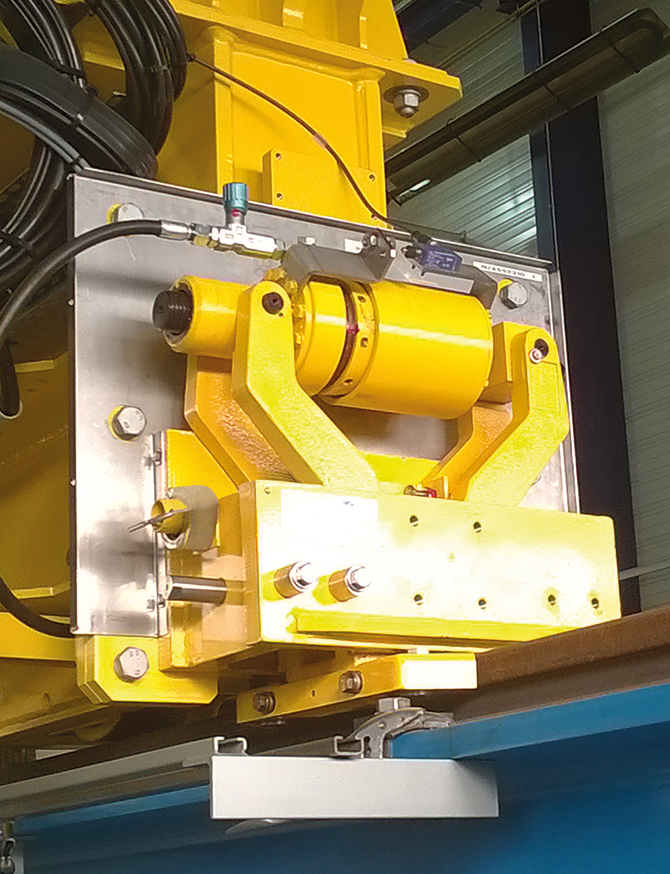

Emergency Brake Calipers and Hydraulic Power Units for Hoists

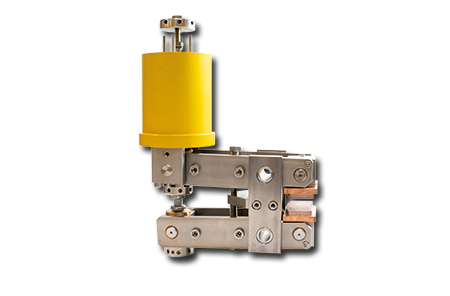

Hydraulic Emergency Brake Calipers

- Available as a fixed caliper version or as a floating caliper version to reduce weight and save space

- Hydraulic chamber mounted above the spring assembly allows for easy and safe brake seal replacement

- Optionally available as a ready-to-install solution with one or two brakes mounted on a pedestal, including hydraulic power unit, terminal box and hydraulic hoses or pipework

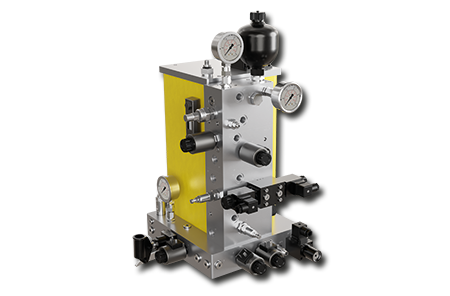

Hydraulic Power Units

- Modular setup allows a wide range of functions in one device

- Large range of options such as controlled braking, brake force adaptation or flank change elimination

- Optional accumulator for faster

- Optional accumulator for faster brake opening times, or ease of hand release

Storm Brakes for Gantry Drives

Rail Clamps and Rail Brakes

- Very high braking force with compact dimensions

- Easy and safe brake seal replacement with top mounted hydraulic chamber

- Suitable for all common rail profiles

- Inductive or mechanical sensors for “Brake open” and “Brake pad wear”

- Corrosion resistant coating up to C5-M (CX)

- Maximum holding force for rail clamp: 500 kN

- Maximum holding force for rail brake: 300 kN

- Rail clamp lateral float up to +/- 30 mm

- Rail clamp vertical float up to +/- 5 mm

Service brakes for Gantry Drives

Electromagnetic Brake DH 034 FEM

- Simple and robust brake design

- Stainless steel levers for highest corrosion protection

- Suitable for dynamic and static applications

- Easy to install and maintain

Electrohydraulic Disc Brakes and Drum Brakes

- Drum brakes available in metric design according to DIN standard 15435 or with imperial dimensions according to AISE standard

- Robust and simple design

- Self-lubricating bushings

- Stainless steel pins and spindles

- Automatic wear compensation

- Organic or sintered linings for disc brakes

- Organic linings for drum brakes

- Optional self centering unit

- Optional throttle valve on the thruster for delayed brake setting

Solutions for extending the service life of hoist gearboxes

Braking systems for port cranes

| Over the years, the size of container vessels have constantly been growing. This development has led to a growth of container cranes as well. Besides the increase in total height and boom outreach, the hoisting speed and maximum load under the spreader has grown, too. The result is an increase of peak torques in the bearings and the crane’s steel structure, when doing a category 0-emergency stop. | RINGSPANN has developed a complete range of braking solutions, that all follow one goal: To minimize the impact of peak torques and backlash to extend the lifetime of the gearbox. |

Flank Change EliminationA flank change in the gearbox occurs when the individual gears in the gearbox briefly lose contact with each other due to strong braking (e.g. during an emergency stop) and results in a damaging shock load. To eliminate a flank change, it is important to brake first on the transmission side, which is on the opposite side of the driving force. When lifting, these are the emergency brakes. When lowering, these are the service brakes. |

Adaptive braking on main hoistFor peak torque reduction, the braking force of the emergency brakes is adapted to match with the lifting situation: The required braking torque for a lifting or lowering process with an empty spreader is lower than the required braking torque for a lifting or lowering process with maximum load. During a lifting or lowering process with an empty spreader, a brake configuration is activated that provides sufficient but not excessive braking force; during a lifting or lowering process with a full load, all emergency brakes close immediately. In both cases, the hoist is safely brought to a standstill. |

Adaptive braking on boom hoistFor peak torque reduction during an emergency stop of the boom, the emergency brake caliper is able to brake with two different braking forces. This is achieved by the pre-selection of two different valve configurations on the hydraulic power unit. The first configuration allows immediate braking, the second configuration allows a 2-Step Braking with a reduced initial braking force which is increased over time. |

Detection of overspeed and gearbox failureWith the RINGSPANN Speed Monitoring Module SMM, we provide a PLC-based control unit which monitors the hoisting speed with the help of a combination of incremental With the RINGSPANN Speed Monitoring Module SMM, we provide a PLC-based control unit which monitors the hoisting speed with the help of a combination of incremental |